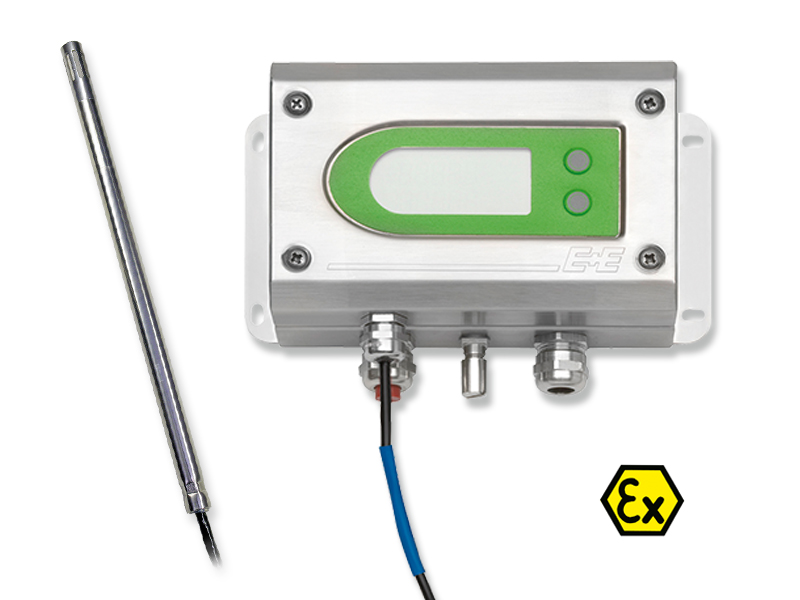

用于高湿及化学污染环境的温湿度变送器

HTS801

HTS801 系列变送器是一款即使在持续高湿和化学污染等苛刻环境中,也能稳定和准确测量湿度(RH)和温度(T)的工业变送器。它温度的量程范围达到-80℃到180℃,耐压高达300 bar,

能够应对非常苛刻的测量环境。

HTS801 分体探头型(T28)可以帮助客户解决气象领域苛刻的测量要求,是客户的理想选择。探头的特别设计使其便于安装防辐射罩。

优异的测量性能

HTS801变送器安装了 E+E 研发的高端湿度敏感元件,使变送器在高湿或严重化学污染环境中也

能保持测量的持续性和准确性。这种集成电路结构形式的湿敏元件结构,加上 E+E 专有的敏感元件镀膜保护,使变送器即使在冷凝或被化学污染后也能快速恢复到正常的测量状态。

多样性和坚固性

HTS801系列可选配六种不同模式的远程探头以及搭配多种长度的延伸电缆,再通过湿敏元件不同的加热模式,HTS801 系列可以完成特定应用环境的各种测量要求。它所配备的聚碳酸酯或金属外壳,达到了防护等级 IP65 / NEMA 4X ,能适配各种接口模块以及电气连接选项。

rapidX 智能探头

HTS801配备了可插拔连接的 rapidX 智能探头,实现了探头热插拔及快速更换。所有的 HTS801 rapidX 智能探头在连接到 HTS801变送器后都会自动上传其特定参数,即使在设备运行期间也可以更换,无需任何配置、调整或校准。此项功能有利于在恶劣的工业环境中(偶尔探头会有损坏)排除停车时间以及节约其相应成本。

输出和组态

HTS801变送器的测量值通过两路模拟通道输出,输出信号为标准电压或电流信号,或者可选配 RS485 (Modbus RTU)或Ethernet-PoE(Modbus TCP) 数字接口。另外,带有继电器输出的报警模块(选项),可实现开关报警和控制。用户可以通过3.5" 液晶显示屏上的按钮或者使用免费的PCS 10专业组态软件对变送器的温度和湿度进行组态和调整。

典型应用

- 砖、陶瓷、木材、混凝土、聚酯纤维等的干燥过程

- 高湿的贮藏室

- 气候、试验箱和固化室

- NMI的气象测量和冰情警报系统

- 燃料电池和汽车测试台

- 制药和化学领域应用

- 燃气发动机的进气监测

- 生物过滤器的监测,尤其是气味强烈的生产设施上

E+E 公司的质保期限和校准服务将延长至5年

我们公司的服务和校准包将保护您的测量设备处于完好状态,提高设备的准确性和可靠性。请为您的E+E 产品选择适合的服务包,您将会有长期专业的设备服务、成本降低以及出色稳定的测量精度。访问这里将找到更多的详细信息。

特征

- 测量精度高

- 高端的集成电路结构形式的湿敏元件

- 温度范围达到-80°C到180°C

- 耐压达 300 bar (4351 psi)

- 加热模式可应对短暂性冷凝和持续性高湿的应用环境

- 自动恢复模式 (ARC)可去除化学污染

- E+E专有镀膜确保了元件的长期稳定性,即便元件应用在苛刻环境中

- rapidX 智能探头,内部储存传感器元件的校验数据

- 3.5” 彩色液晶显示屏,带按钮和记录功能

- 两路模拟输出电压/电流

- 报警指示功能(根据NAMUR)

- RS485(Modbus RTU) 或者Ethernet-PoE (Modbus TCP) 数字接口

- 2个可自由配置的报警输出

- 聚碳酸酯/不锈钢外壳,防护等级IP65 / NEMA 4X

- 可计算所有湿度相关的物理参数

技术资料

- 测量范围

- 0...100 % RH

-80...180 °C (-112...356 °F) - 精度

- ±0.95 % RH

±0.1 °C (0.34 °F) - 耐压范围

- Up to 300 bar (4 351 psi)

- 数字接口

- RS485 with Modbus RTU

Ethernet-PoE with Modbus TCP - 输出

- 0-1/5/10 V

0/4-20 mA - 供电

- 24 V AC/DC

相关产品

下载 HTS801

FAQ

Use the RS485 kit for retrofitting (order number HA010605), see the data sheet and operation manual of your specific E+E product.

The device indicates an error according to NAMUR NE43. For details, please see the user manual of your specific E+E product.

The device has one GND connection for the power supply, an analogue output GND and an interface GND, see connection diagram in the user manual. The analogue output GND and the interface GND carry only the current output resp. interface current, which results in a more stable signal compared to a mix GND connection.

Press 2x ► | 5x ◄ | 1x ▲ | 3x ◄ | 1x ▼ | 1x ► then select the "Configuration menu" and press ENTER. Scroll down to “Diagnosis”, press ENTER and scroll down to “Password protection” here you can see the previously set password.

Connect the device via the USB service interface to a PC running PCS10 Product Configuration Software and read out the communication setting.

Alternative for device with display: the display configuration menu has a section for Modbus settings (RS485, Modbus RTU) or IP settings (Ethernet, Modbus TCP) where you can see the actual setting or change it.

Connect the device via the USB service interface to a PC running PCS10 Product Configuration Software and see at the section "Log data download" for the data memory status.

Remote probe types can be retrofitted with an Ethernet interface using HA010606, see data sheet and operation manual of your specific E+E product.

The measured data logged by the device can only be downloaded via the USB service interface to a PC running the PCS10 Product Configuration Software.

High dew point means the difference between the ambient temperature and the dew point temperature is lower than 3 °C (5,4 °F), which corresponds to RH >85 %.

The appropriate product is the HTS801-M4T7. The device features a heated sensing element and probe body (dual heating system).

Due to the direct contact of the HTS801 sensor element with the measurement medium, chemical contaminants (e.g. VOCs / vapors) can penetrate the sensor polymer and cause drift effects.

Automatic ReCovery (ARC) is used to remove this chemical contamination and thus eliminate possible drift effects of the RH /T sensing element. This is accomplished by intense heating of the sensing element.

Deviations due to chemical contamination and how fast they occur depend mainly on the concentration of the chemicals, the duration of the contamination, the temperature, and the type of chemicals.

The ARC trigger interval must be determined according to the drift response time and tolerable measurement errors. As a starting point, it is recommended that ARC be triggered every 24 hours. From there, the intervals can be optimized in a range from 1 hour to once per week. Additionally using the ARC module or Modbus commands the function can be triggered at or after a certain process step.

No. For low Dew Point measurement EE355 / EE371 are the right products, which have an auto-calibration function to ensure ±2 °C Td accuracy. The HTS801 calculates the Td values down to -80 °C according to its possible temperature range and is able to scale its analogue outputs accordingly. The HTS801 Td accuracy results from its RH and T accuracy at the operating point. The E+E Humidity calculator helps to determine the Td accuracy.